Hey amigos! Hope you are doing well.

Today, we will be wading into the Plywood vs HDHMR debate and presenting facts about the differences between the two products along with additional related information.

Let’s get started!

HDHMR vs Plywood

To begin with, HDHMR is a type of plywood that stands out amongst all other types. It’s completely different & superior in terms of maintenance, features, and advantages to commercial plywood.

However, most Indian customers aren’t aware of HDHMR and its benefits compared to other types of plywood.

For the past many decades, commercial plywood has been the preferred option of Indians for fixed furniture. This has started to change over the last decade or so, with HDHMR emerging as the first choice of architects & interior designers when designing homes for their clients.

This has led to HDHMR becoming the most in-demand product compared to plywood. It won’t be an understatement to say that HDHMR has taken over the plywood market to a significant degree.

Find below the key differences between HDHMR & Plywood:

|

HDHMR |

Plywood |

|

Superior quality wood |

Inferior quality wood |

|

Tougher than any plywood available in the market |

Not as tough as HDHMR |

|

Not susceptible to attacks from termites, borers & fungus |

Susceptible to termite infestations, borers & fungus |

|

Highly resistant to moisture |

Affected by moisture & humidity levels in the air |

|

Offers innovative applications |

Doesn’t offer innovative applications |

Later stages of product category development:

Following are the products that comprise the later stages of product category development of plywood:

- MDF

- HDF

- Boilo

- MR Ply, Marine Ply, BWP (Boiling Water Proof), BWR (Boiling Water Resistant)

- HDHMR (High-Density High Moisture Resistant)

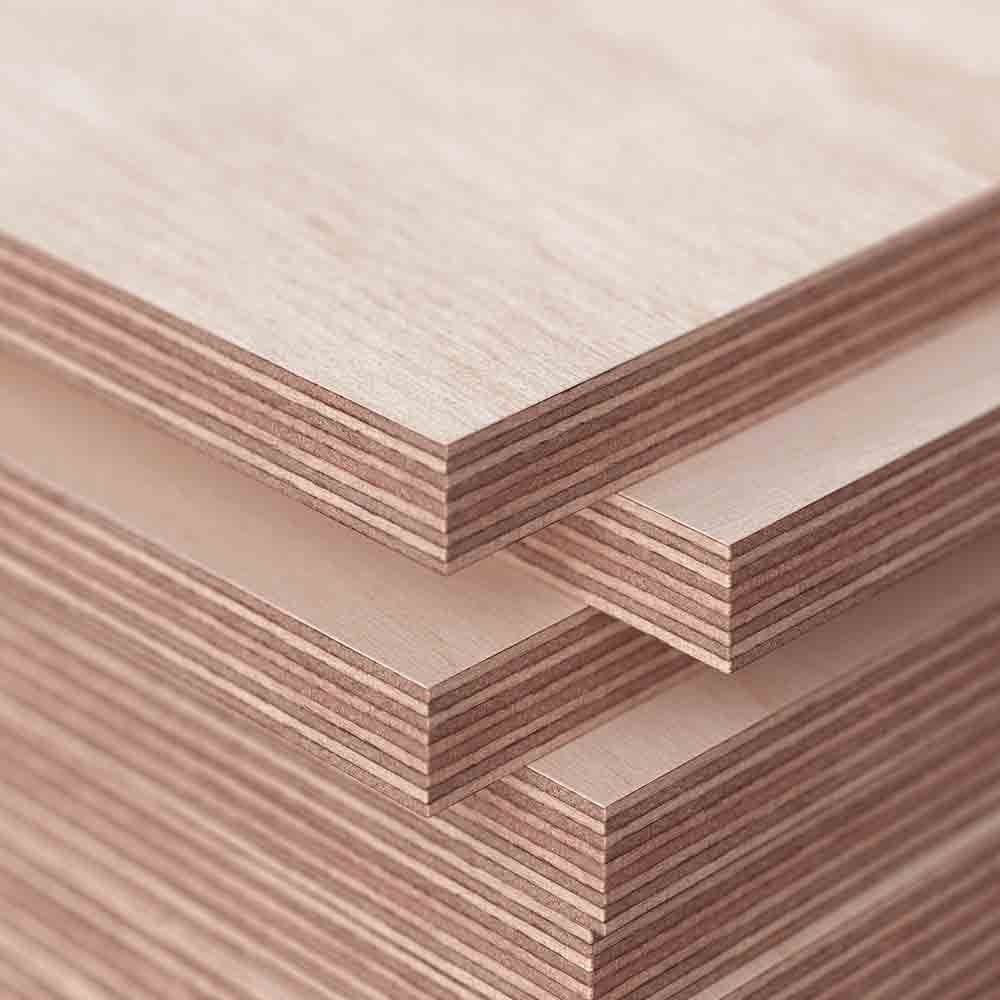

Manufacturing Process of Plywood

Plywood is manufactured by applying glue to thin layers of wood (called as ply/plies), binding them together with a resin under high pressure. This results in the creation of a thick, strong & flexible flat sheet known as plywood.

Types of Plywood

The various types of plywood and their quality are determined by the kind of wood used, their application & process. Having said that, the 3 common types of plywood used in India include MR ply, BWR & BWP ply, and Marine ply.

Let’s get to know the different types of plywood available in the market.

Commercial plywood

Generally preferred for furniture used in dry areas such as living rooms, study rooms, offices, etc. Used to make wall panelling, partitioning, etc.

MR Ply

MR stands for Moisture Resistant. MR Ply exhibits excellent resistance to moisture in damp & humid conditions but isn’t waterproof. It’s a favoured plywood material in tropical areas.

BWP Ply (Boiling Water Proof Ply) & BWR Ply (Boiling Water Resistant Ply)

As the name suggests, BWP Ply is waterproof to a certain degree, while BWR sheets resist moisture to a particular extent.

These ply sheets are generally used in bathrooms & kitchens due to their respective waterproof and water-resistant properties.

Marine Ply

Marine plywood stays true to its name as it’s waterproof to a large extent. It comprises high-quality ply and is used in the interiors & exteriors of marine vehicles. It’s also utilised in kitchens & bathrooms.

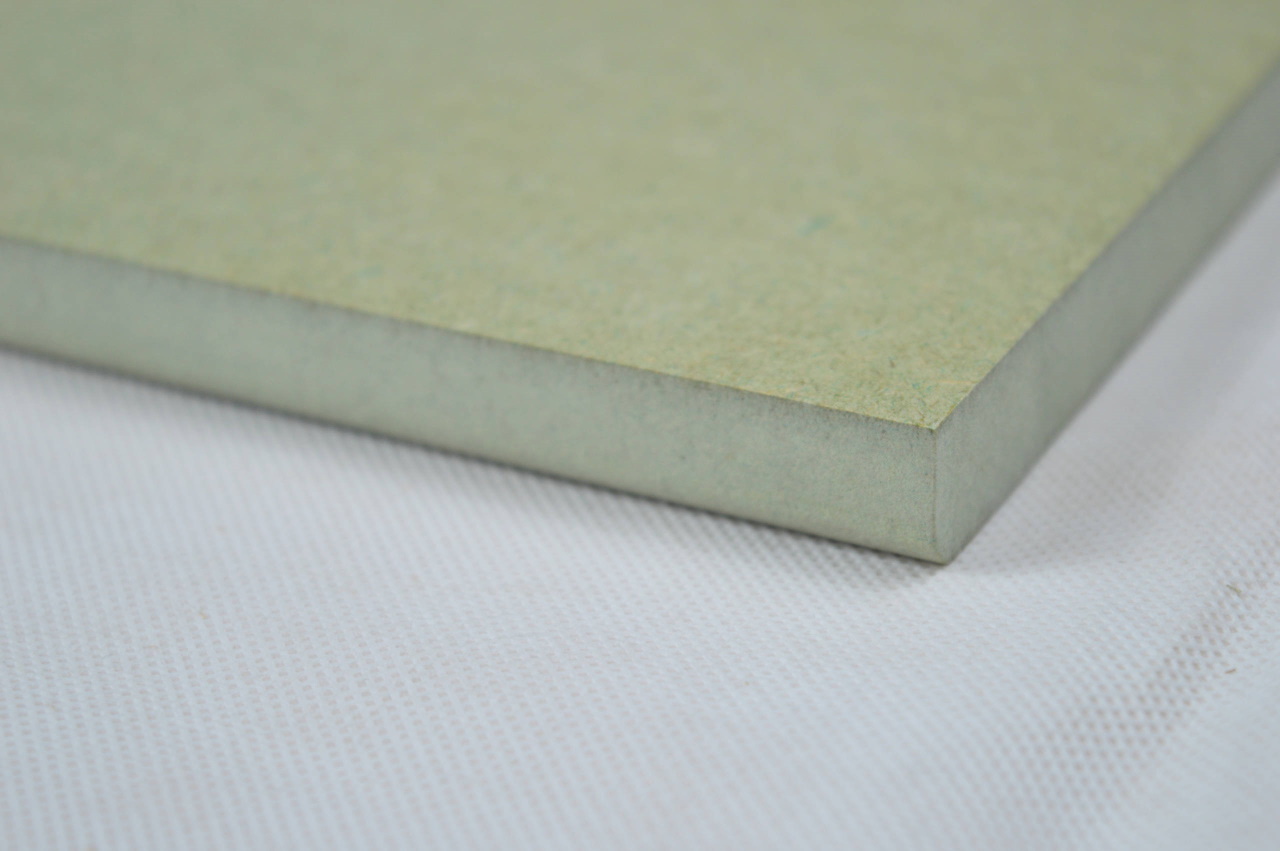

HDHMR (High-Density High Moisture Resistance) Board

Manufacturing HDHMR involves combining fibre chips & forest wood waste via a homogeneous construction process.

Fibre chips are pressed together to assemble a single layer, discarding small wood content to create a strong high-density board. The density is superior to other plywood products available in the market.

HDHMR’s unprecedented quality and long list of applications are transforming the Indian interior industry by taking over the market of plywood.

HDHMR Product Advantages

Some of the HDHMR product advantages we haven’t discussed already include:

- Special glue used makes it a water-resistant product to suit Indian weather conditions

- Can be used in highly moist areas & climates

- Smooth surface that can be polished with colours of choice

- Innovative applications

- Cost-effective panelling solution

Key Applications of HDHMR:

- Kitchen Shutters

- Door Shutters

- Cafeterias

- Gyms

- Desks & Lockers

- Hospital

- Offices & Residential Areas

- Ideal Substitute for Flush Doors

- Packing Industry

- Panels

- Outdoor Fixtures

Amazing Fact about HDHMR:

The statement that HDHMR is a revolutionary product is proven by the fact that even if you keep it underwater for ten days, zero defects will emerge in the product.

Conclusion

HDHMR is basically an advanced & enhanced version of plywood and is the perfect option for creating robust & sturdy furniture.

It also provides excellent aesthetic value due to its ready & smooth surface that can be coloured with various gradient colours. It’s also great in terms of maintenance, as HDHMR materials can be cleaned with lukewarm water.

Get A Free Quote

Looking for the Top 5 Considerations for Designing Your Perfect Kitchen?

The kitchen holds a special place in Indian homes, symbolizing both functionality and emotional significance. When designing or planning your kitchen, these top 5 considerations will help you create a space that perfectly caters to your needs and aspirations. 1....

Advantages of Choosing a Modular Kitchen from an Architectural Company Over Traditional Carpentry

Introduction: The kitchen is often referred to as the heart of the home, a place where families gather to share stories, love, and create memories. In today’s fast-paced world, where time is a precious commodity, the need for efficient and hassle-free solutions in the...

What is the difference between Marble and Granite?

Hey guys! Hope you are having a great day. Today we are going to discuss the difference between marble and granite. You may be aware that over the past 3 decades or so, marble and granite have been two of the most popular materials for kitchen tops in India. Through...

Promkraft Factory Virtual Tour

Hi guys! Hope you are doing well. Have you ever wondered what it would be like to see how your modular kitchen is prepared, the various raw materials, machines & technologies used during the manufacturing process, etc. Promkraft makes this possible through our...

Which Unique Design To Choose For A Classy And Luxurious Kitchen Look?

Once upon a time, and for a very long time, Indian kitchens were dreary disorganized workrooms, conspicuously hidden from the rest of the house. It was a place none but women entered, except in urgent and inevitable circumstances. Ladies, young and old slogged,...

Glass Top – The Most Unique Kitchen Platform

Hi, folks! All good? At the apparent fag end of the pandemic, when the whole world is beginning to return to normal as before, we at PROMKRAFT present another enlightening story of very useful information that is otherwise hard to come by. That kitchens and kitchen...

Solvent Based PU Colour or water Based PU Colour – Which ones to choose?

Hey there, folks! We are back with some more useful gyaan on better living. Today, let’s know more about the paints that go into making our homes and prized possessions look zingy. Regular Polyurethane (PU) colours are made from pigments in the form of thick...

Glossier than acrylic – Brillanteo Gloss to next level

Brillanteo - a product by Promkraft that the entire world is going to cherish for a long, long time!! In 2010 we at Promkraft pioneered the introduction of acrylic as a building material for kitchens. We conceived and popularised this novel concept that set trends in...

Let’s understand which acrylic to be used for the kitchen and furniture

Our home is our haven; a cocoon where we breathe freely, feel passionately, think clearly and dream lovingly. It shows our attitude, perspective and our outlook towards life. Every part and corner of it is our unique signature that reflects our personality and the...